Machine manufacturing

- Uzbekistan’s investment potential

- Investment legislation

- Investment offers

- Industries

- Guide for Investor

- Visa issues

- FEZ and SIZ

- Empty buildings and lands

- «Benchmark Uzbekistan vs. Other countries»

- Interactive maps

- Ongoing investment projects

- Investment projects implementation database

- Online Investor Questionnaire

- Benefits and preferences for foreign investors

- Foreign credit lines

- General System of Preferences (GSP +)

Uzbekistan is currently actively implementing a policy of raising the level of competitiveness of the country on the basis of technical and technological breakthrough in the real economic sectors. Mechanical engineering, the development of which is a symbol of the country’s industrial progress, should play a leading role in this process.

Automotive industry

From the mechanical engineering industries since the first days of independence, the automotive industry has been actively developing in Uzbekistan.

Currently, the Republic of Uzbekistan is the largest car manufacturer in Central Asia and takes the second place among the CIS countries with a high share of localization (about 45-55%) in passenger cars and about 15-30% of trucks and buses.

Production activity is characterized by the following indicators:

|

Manufactured products in the amount of |

10 792 billion UZS |

|

The growth rate by 2016 amounted to |

167,1% |

As of 01.01.2018 the industry employs 24.77 thousand people.

Through the state-owned company Uzavtosanoat, a number of global brands have been localized in various segments, including passenger cars and LCV (General Motors), trucks (MAN, ISUZU) and bus (ISUZU). However, in almost all joint ventures, the controlling stake is controlled by the state through Uzavtosanoat – 75% in GM Uzbekistan – 51% in a joint venture with MAN, 84% in a joint venture ISUZU and 50% in a joint venture with PSA.

The volume of production of passenger cars amounted to 140.2 thousand units. (159.1% by 2016), buses and trucks ISUZU – 3600 pcs. (105.3%), MAN trucks and buses – 1200 pcs. (119.4%), batteries – 680.2 thousand units (116.3%), power units – 91.6 thousand pcs. (2.1 times).

The enterprises of the company produced consumer goods in the amount of 6,686.2 billion UZS, with the growth rate by 2016 – 156.4%.

Today, the demand for cars in the domestic market is covered by 60-70%. Also trucks by 50%.

Currently, the government of the country is actively engaged in attracting foreign direct investment in the automotive industry as an independent player for the development of competition and production of the industry.

Currently, the industry has 23 joint ventures that produce cars, buses, trucks, components and nodes for cars, as well as consumer goods.

The following companies work in the field of automobile production:

- Joint stock company GM Uzbekistan, created jointly with General Motors for the production of cars,

- Samarkand Automobile Plant for production of buses and middle-class trucks, which are founded along with UzAuto by Japanese companies Isuzu and Itochu,

- the joint Uzbekistan – Germany enterprise MAN Auto Uzbekistan for the production of heavy trucks and buses.

- UzAuto and Peugeot Citroen Automobiles signed an agreement on establishing joint venture, according to which a new plant for production of light commercial vehicles is being built in the city. The project provides for production of different configurations of cars Peugeot Boxer and Peugeot Expert on a full cycle.

The enterprise UzAuto TRAILER was established for the production of mounted and trailed equipment, as well as Kamaz trucks are assembled together with a Russian company.

For the production of auto components, about 40 large enterprises of UzAuto work in this area, most of which are joint ventures with leading global manufacturers of auto components such as Korea Delfi, Erae, Sungwoo Hitech, Austem, AMS, KM&I, etc.

In addition, the delivery of auto components is provided by more than 160 small and medium independent suppliers.

In particular, jointly with General Motors and UzAuto, a joint venture GM Power Train Uzbekistan was established for producing engines of 1.2 and 1.5 liters. The plant is the only enterprise in the global network of General Motors where the casting of aluminum products, the machining of component parts and the full cycle of assembly and testing are carried out in one plant.

UzAuto, along with its production activities, attaches great importance to qualifications and personnel education, is the founder of educational institutions, such as the Turin Polytechnic University in Tashkent, the Academic Lyceum of the University, as well as mechanical engineering colleges in Andijan and Samarkand.

A striking example of the high potential of localization enterprises of UzAuto is the supply of automotive components to the conveyor of foreign auto manufacturers. UzAuto enterprises supply a solid list of automotive components to manufacturers’ conveyors in 5 continents of the world. The staff of enterprises has sufficient qualifications for ensuring the process of development, production and delivery of products. Introduction of world standards in production and quality management, the availability of a number of international certificates, as well as equipping enterprises with necessary laboratory testing equipment allows to produce products that meet international standards. Such systems as GMS, 5S, Kaizen and others have been introduced at UzAuto enterprises.

Based on the existing level of localization in the industry, there are a number of promising localization projects:

- Stamped parts

- Plastic parts

- Cast iron parts

- Mechanical processing of brake discs and drums

- Audio system

- Plastic tanks for cars

- Wheel

- Suspension springs for cars

- Shock absorbers for cars

- Spark plug

- Extrusion for rubber seals

- Switches for cars

- Rearview mirror

- Roller forming

- Plastic pedals

- Electric motors for cars

- Shift knobs

- Wipers and wiper mechanism

- Seat belts for cars

- The axis of the car

- Steering column

- Steering gear

- Brake system parts

- Brake pads

- Connectors and covers for 522 connectors

- Hoses, tubes

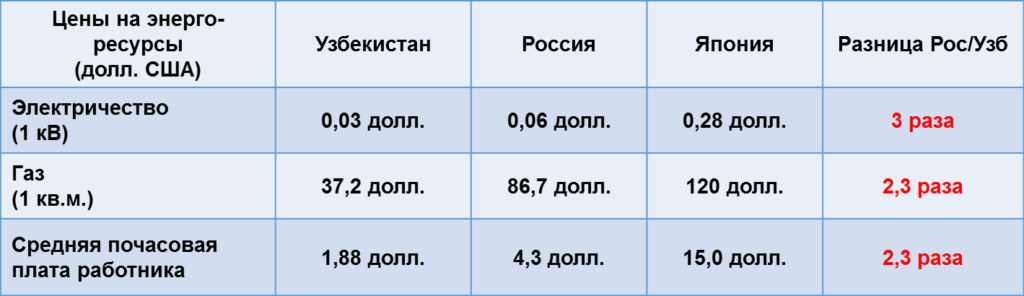

Comparative low cost of Uzbekistan automotive products:

- a package of tax benefits and state support measures on individual resolutions of the President of the Republic of Uzbekistan and the Cabinet of Ministers; (RP-800 of February 21, 2008; RP-1020 of December 16, 2008, RP-1736 of April 4, 2012 and others).

- Resolution of the President of the Republic of Uzbekistan of 01.07.2018, No. RP-3028 “On measures of further improving the management and accelerated development of the automotive industry for 2017-2021”.

- agreement on a free trade zone between the CIS countries;

- availability of raw materials (copper, lead, metal, zinc, polypropylene, polyethylene, rubber, and others);

- multi-level quality control system

- affordable and skilled labor (Turin Polytechnic University, Turin Academic Lyceum in Tashkent Polytechnic College in Samarkand city and Andijan region);

- low cost of energy;

- modern production facilities with necessary infrastructure;

- optimal logistics costs.

Cost comparison

Agricultural engineering

The most potential branch of mechanical engineering, which has all the necessary components for its development, is agricultural engineering.

Production of agricultural machinery for the Republic of Uzbekistan is one of the key strategic sectors. In addition to production volumes – about 8 thousand units in 2017, of which about 1.2 thousand tractors and 0.3 thousand combines, important success has been achieved in this industry in the last few years.

As of July 1, 2018, the park of agricultural machinery in the Republic of Uzbekistan amounted to 150,486 units, including 57,822 units of tractors, 58 019 units of mounted equipment, 3,608 units of combine harvesters, 1,224 units of cotton harvesting machines, 1,738 units of forage harvesting equipment, 28,075 units of other agricultural machinery.

Of the above quantities of available agricultural equipment, 82 921 units are obsolete with a lifetime of 11 years or more, including 30,412 units of tractors, 28,071 units of mounted equipment, 1,131 units of combine harvesters, 175 units of cotton harvesting machines, 919 units of forage harvesting equipment, 19 894 units of tillage equipment, 1 445 units of equipment for various types of fertilizers and plant protection, 2 473 units of other agricultural equipment, which creates a shortage of equipment in the peak season of conducting agrotechnical work.

Based on the analysis of the park of agricultural machinery, agricultural producers need an additional 100,670 units of equipment, of which 26,139 units of tractors, 34,605 units of mounted and trailed equipment, 1 149 units of combine harvesters, 3,080 units of cotton harvesting machines, 9 951 units of forage harvesting equipment, 22 278 units of tillage equipment, 2,968 units of equipment for various types of fertilizers and plant protection and 500 units of other equipment.

At the same time, 55.1% of the existing equipment are morally and physically obsolete, needs to be updated at an accelerated pace, as this affects the increase in the productivity of cultivated land, the growth of crop yields and, of course, the increase in exports of fruits and vegetables.

In the Republic of Uzbekistan, production facilities of various types of agricultural machinery of a number of national and world brands such as JSC Tashkent Plant of Agricultural Machinery, JSC Chirchik Plant of Agricultural Machinery, JSC Technolog, JSC Aggregate Plant, LLC Agrikhim, JSC Urgenchkormmash, LLC Uz CLAAS Agro, LLC UzKeysMash, LLC UzKeysTractor, LLC DD-Agroteckmash, Kuhn, LLC UzAgrotex Sanoat Invest, LLC Lemken-Chirchik and LLC Amkodor-Agrotechmash, which produce tractors of various capacities, grain and fodder harvesting combine harvesters, mounted, trailed, road-building and specialized equipment, have been established.

For the period from January 1, 2018 to June 30, 2018, the above enterprises cumulatively produced more than 6,000 units of equipment worth 1 449.5 billion UZS. At the same time, the growth rates of production and sales indicate the presence of demand for agricultural machinery.

Firstly, this industry has strong domestic demand. Agriculture in Uzbekistan in terms of the volume of production exceeds 20% of GDP, about 30% of those employed and is one of the main sectors that ensure sustainable development of economy. A wide range of agricultural products is grown in Uzbekistan, including industrial crops such as cotton, oilseeds (sunflower, rapeseed, safflower), vegetables, fruits, melons and gourds, certain types of citrus fruits, and fodder crops, each of which requires not only universal agricultural machinery, but also special.

Secondly, external demand for agricultural engineering products can be supported, at a minimum, at the expense of the neighboring states of Central Asia, as well as Afghanistan, which do not have their own agricultural engineering with a sufficiently developed agriculture.

Thirdly, agricultural engineering in Uzbekistan has a certain design base, scientific-technical potential for its further development.

Fourthly, a system of training personnel has been established, capable of not only using, but also producing and designing agricultural machinery.

Thus, there is a chain of interconnected industries (the so-called cluster), which allows relatively quickly create a competitive mechanical engineering industry that is efficient in the domestic and foreign markets.

1) further improvement of the legislative framework aimed at supporting the increase in demand, availability of upgraded agricultural machinery:

- preservation of existing benefits for enterprises of agricultural engineering, subject to an annual increase in the level of localization of not less than 5%;

- development and adoption of normative-legal acts aimed at introducing a progressive scale of utilization collection for agricultural equipment after 7 years from the production date, its repeated (secondary) implementation, as well as sending accumulated funds to finance the replenishment of working capital, implementation of investment programs of agricultural enterprises and financing the sale of finished products through specialized financial institutions;

- introduction of environmental standards in the import of finished products;

- creation of a normative-legal framework to finance export sales through a network of own leasing companies in foreign countries;

2) creation of favorable conditions for further development of the agricultural engineering industry, its investment and commercial attractiveness by organizing an industrial technopark of agricultural machinery with participation of private and foreign capital;

3) further development of service and dealer points;

4) phased transition to a system of centralized procurement of components, raw materials and supplies;

5) adoption of specific measures aimed at reducing costs by updating the fleet of equipment, as well as revising the norms of costs of raw materials, and introduction of new energy-saving technologies;

6) increasing production and sales volumes by presenting buyers with preferential leasing interest rates;

7) raising the level of qualification of the industry employees

8) development of research and development, introduction of new types of energy-saving equipment into production.

Further development of research and development will help agricultural engineering enterprises to master new types of agricultural equipment.

Research work will be aimed at:

- development of a machine plume based on the requirements for carrying out agrotechnical measures for growing crops during tillage, sowing and harvesting, its transportation, etc.;

- development of new types of high-performance and energy-saving equipment;

- creation of multi-functional equipment that will allow to implement up to 4 land tillage, sowing and planting operations at the same time;

- unification of designs of agricultural machinery;

- development of a design of a new domestic universal tilled tractor with increased ergonomic indicators.

Since investments in research and development work take quite a long time and significant financial resources, government support is expected in the form of subsidizing its development. Research work will allow the introduction of machinery adapted to the climate and soil of the Republic of Uzbekistan, taking into account the requirements for agrotechnical work, improve production process, free from financial burden in the form of royalties paid to foreign partners.

Direction of investment in deepening localization of products in 2018-2020 will allow to master the component base of agricultural equipment. In addition, these events will allow developing scientific technical potential of the staff of the design and technology center in real conditions.

For the period of 2018-2020, it is expected to master production of the component base for deepening the localization of agricultural equipment:

- tooling, molds and dies;

- foundry metal products;

- tractor and other types of transmission gears;

- cabins of self-propelled agricultural machinery (expansion of production);

- rims;

- plastic and rubber products;

- hardware group of various types;

- electrical parts.

- own funds of buyers;

- credit funds of commercial banks;

- borrowed funds of foreign financial institutions;

- funds from international financial sources;

- funds of state support for agriculture under the Ministry of Finance of the Republic of Uzbekistan;

- funds of leasing companies and other financial institutions;

- funds received from the payment of the utilization fee.

- target export credits of domestic banks, refinanced by national banks of neighboring countries;

- attraction of borrowed funds of foreign banks of residents of foreign countries;

- funds of leasing companies;

- loans of the Ministry of Finance of the Republic of Uzbekistan;

- funds received from the payment of the utilization fee.

- own funds of enterprises;

- loans with an interest rate of no more than 50% of refinancing rate;

- funds provided for by the Resolution of the President of the Republic of Uzbekistan of November 17, 2016 No. RP-2658 “On measures of organizing activities of the joint-stock company “Uzagrotechsanoatholding”;

- funds received from the payment of the utilization fee.

- own funds of enterprises;

- loans with an interest rate of no more than 50% of refinancing rate;

- private investment;

- direct foreign investments;

- funds from international financial sources;

- funds received from the payment of the utilization fee.

Domestic enterprises have huge plans ahead, and most of them are connected with attracting strategic partners from abroad. For example, by the end of this year, the Russian company Rostselmash will start assembling its machinery at the facilities of Chirchik plant of agricultural machinery.

The first batch of Russian machinery produced in Uzbekistan will consist of 20 self-propelled fodder harvesting machines of three types. The parties have also already begun to work on the issue of jointly mastering the assembly of highly demanded hay balers in the country. Their production will amount about 200 units per year. In general, the annual demand of the market of Uzbekistan is estimated at 300-400 units of such equipment.

After the full launch of the project, several hundred Russian-made agricultural machines will be produced annually in Chirchik – about seven models of forage harvesters and self-propelled lawn mowers. In addition, the Russian side will gradually increase the level of localization of products manufactured in the country.

Another interesting project – the Belarusian Scientific Research and Development Technological Institute of Foundry BELNIILIT and Uzagrotechsanoatholding are implementing a project on creating the country’s first automated foundry for agricultural machinery.

Foundry is considered one of the most important components, which provides deep localization, allows to reduce the cost of agricultural equipment and produce products with high added value. To date, BELNIILIT has developed the technical documentation for this project, it is planned to complete it before the end of the year.

In addition, partnership in foundry is actively developing with Uzbekistan Railways, which launched in 2013 a foundry-mechanical plant with a total cost of $ 150 million. It is equipped with technological lines of German companies and is the only one in the region capable of producing foundry products for railway transport.

Uzagrotechsanoatholding invited representatives of the Italian and Korean companies that produce agricultural equipment to evaluate the quality and technology of the mechanical foundry in order to use its capacity to localize the production of parts in Uzbekistan.

Contacts

100060, Uzbekistan, Tashkent, street Taras Shevchenko, 34

+998 (71) 202-02-10

Any use (reproduction, publication, copying, reprinting, distribution, translation, broadcasting, processing and other methods of distribution) of the materials of the Investment Portal - Invest.gov.uz, without indicating the original source and a link to the Portal is strictly prohibited!